Dimethyl disulfide (DMDS) has a variety of industrial uses. Its main uses include:

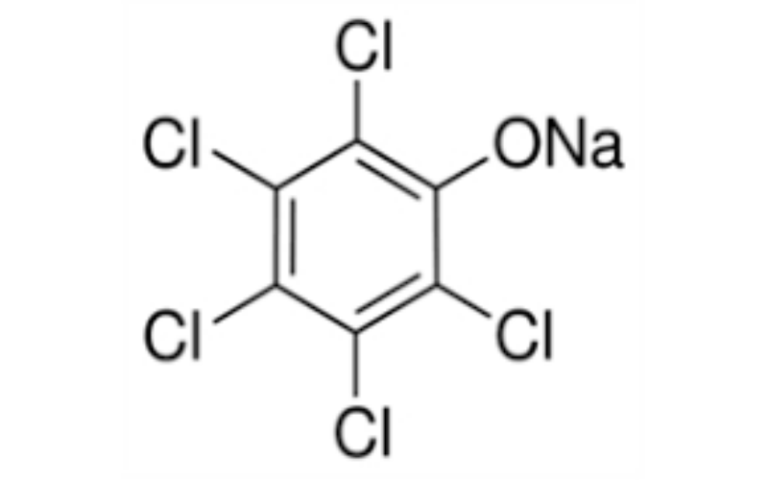

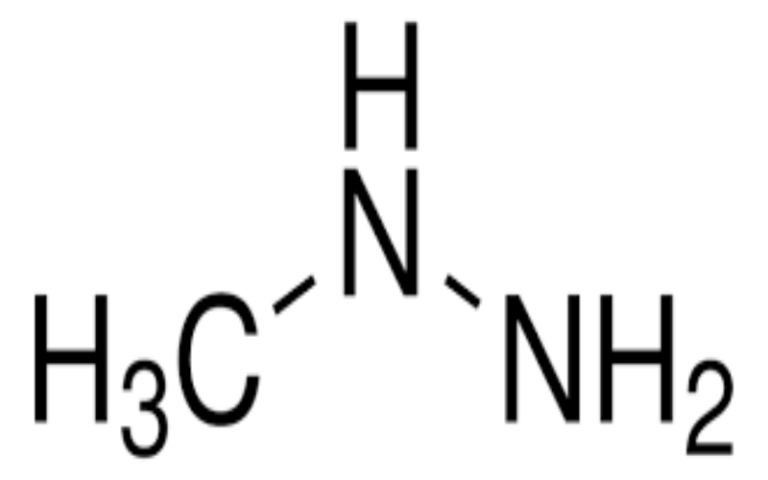

- Pesticide Intermediate: Dimethyl disulfide is used in the synthesis of organophosphorus insecticides, such as the intermediate p-tolyl methyl phenol for fenthion and mitam and the intermediate p-tolyl phenol for phoxim.

- Solvent: It serves as a solvent in various chemical reactions and industrial processes.

- Catalyst Poisoning Agent: In the preparation of catalysts, dimethyl disulfide can be used as a catalyst poisoning agent.

- Coking Inhibitor: In ethylene cracking furnaces and refining units, dimethyl disulfide is used as a coking inhibitor to reduce the formation of coke and carbon monoxide.

- Food Flavoring: According to the regulations of GB 2760-1996, dimethyl disulfide is also used as a food flavoring.

- Chemical Synthesis: In organic synthesis, dimethyl disulfide acts as an important reagent, participating in a variety of chemical reactions.

- Natural Gas and Propane Applications: Due to its unique odor, dimethyl disulfide is used as an odorant for natural gas, supplementing mercaptan compounds.

- Steam Cracking Applications: In the steam cracking process that converts hydrocarbons into ethylene and propylene, dimethyl disulfide is used as a pre-sulfurizing agent, added to the feedstock to reduce the formation of coke and carbon monoxide during high-temperature pyrolysis.

- Fuel Additive: Ethylene oxide containing dimethyl disulfide can be used as a monopropellant for rocket engines to prevent blockage of exhaust nozzles and carbon deposition on the surfaces of combustion chambers.

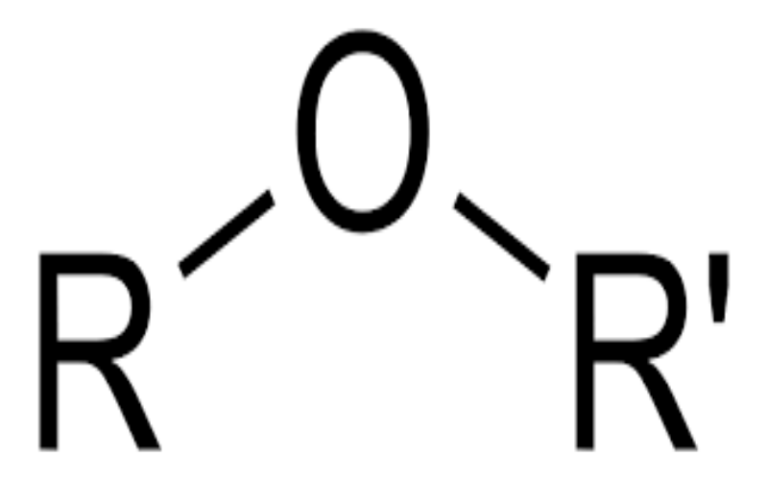

- Extraction Solvent: Dimethyl disulfide has advantages as an extraction solvent because it does not form dangerous peroxides and has low affinity for mineral acids, preventing the extraction of these acids from aqueous solutions.

Our company specializes in hazardous chemicals, flammable and explosive chemicals, toxic chemicals (legal export), ultra-pure and high-purity reagents. Welcome to contact us.

Packing and shipping

.webp)

-1.webp)

-2.webp)