does ethylene glycol evaporate?

Chemical Composition and Properties

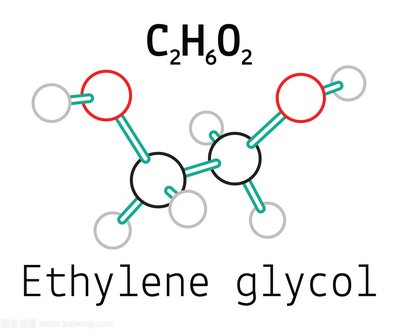

At its core, ethylene glycol is an organic compound with the molecular formula C₂H₆O₂. It is a diol, meaning it contains two hydroxyl (–OH) groups, which contributes to its high solubility in water. Ethylene glycol appears as a clear, colourless liquid with a sweet taste—though it’s toxic and should never be ingested. Its density is approximately 1.113 g/cm³, and it has a boiling point of 197.3°C, making it a stable compound under normal conditions.

One of its standout characteristics is its ability to lower the freezing point of water while simultaneously raising its boiling point. This physical property is why ethylene glycol is a cornerstone in automotive and industrial cooling systems. Its low evaporation rate and high viscosity also make it less prone to volatilization under standard temperatures. For more detailed insights into its properties, refer to resources like PubChem and Wikipedia.

Common Applications

Ethylene glycol has found its way into a multitude of industries thanks to its unique properties:

- Antifreeze in Vehicles: Its most notable use is as a component of antifreeze, where it prevents coolant from freezing in low temperatures and boiling in high temperatures. This double-action makes vehicles efficient in both summer and winter climates.

- Industrial Cooling Systems: Ethylene glycol is commonly used in industrial refrigeration and cooling systems to regulate temperatures in large-scale operations like manufacturing plants or data centres.

- De-icing Solutions: Airplanes often rely on ethylene glycol-based fluids to de-ice their wings, ensuring safe take-offs during winter.

- Production of Polyester Fibres: Beyond cooling systems, it plays a vital role as a raw material in producing polyethylene terephthalate (PET), widely used in plastic bottles and textiles.

- Other Uses: It is also used in paints, inks, and hydraulic brake fluids due to its solvent properties. For more on its practical uses, you can explore this detailed guide from Lab Pro Inc..

These applications underline why ethylene glycol is indispensable in various industries. Its thermal regulation capability and chemical versatility make it a go-to for numerous specialized tasks.

Does Ethylene Glycol Evaporate?

Ethylene glycol is widely known for its use in antifreeze and as a key ingredient in industrial cooling systems. However, its evaporation properties often raise questions. Understanding whether ethylene glycol evaporates and what factors influence this process is essential for handling and storage, as well as preventing environmental or safety-related impacts.

Physical Factors Influencing Evaporation

The evaporation of ethylene glycol, while significantly slower compared to water, does depend on several physical factors. Let’s break these down:

- Temperature: Temperature directly affects the evaporation of any liquid, including ethylene glycol. As the temperature increases, the molecules of ethylene glycol gain energy, though its high boiling point (197.3°C) ensures that substantial evaporation is unlikely under typical conditions. While a small amount may evaporate at elevated temperatures, the rate remains negligible compared to more volatile substances.

- Pressure: A lower atmospheric pressure can encourage evaporation. In high-altitude areas where air pressure is reduced, evaporation can increase slightly. However, even under these conditions, ethylene glycol’s evaporation rate is minimal due to its low vapour pressure.

- Exposure to Air: The surface area exposed to air plays a role in evaporation. If ethylene glycol is uncovered in a wide, shallow container, it may lose a minimal amount to evaporation over time. Yet, its hygroscopic nature often counteracts this by absorbing moisture from the air instead.

For more technical insights and studies on evaporation characteristics, see this research article from ACS Publications.

Comparison with Other Liquids

When it comes to comparing the evaporation rates of ethylene glycol with water or similar compounds, the differences are striking. Ethylene glycol’s structure, vapour pressure, and intermolecular forces make it far less prone to evaporation.

- Compared to Water: Water, with a lower boiling point (100°C) and higher vapour pressure, evaporates readily at room temperature. In contrast, ethylene glycol’s evaporation rate is nearly negligible under similar conditions. This makes water evaporation a familiar phenomenon while ethylene glycol remains much more stable.

- Compared to Other Organic Liquids: Ethylene glycol also evaporates more slowly than many comparable organic compounds. For instance, alcohols like isopropyl alcohol (boiling point ~82°C) evaporate far more quickly, as their lower molecular weights and weaker intermolecular forces facilitate rapid volatilization.

For anecdotal discussions and practical observations regarding its evaporation traits, you can explore this topic further on platforms like Reddit Chemistry.

Understanding these characteristics not only clarifies why ethylene glycol is used in specific applications but also highlights its stability when exposed to typical environmental conditions. Despite external factors, it remains a relatively non-volatile substance.

Implications of Ethylene Glycol’s Evaporation

Ethylene glycol, commonly found in antifreeze and industrial cooling systems, is widely used due to its thermal properties and stability. However, the evaporation of ethylene glycol can have significant implications, both for its performance in technical applications and for the environment. Understanding these effects is crucial for proper handling and maintaining safety.

Impact on Antifreeze Performance

Evaporation plays a limited but crucial role in determining how antifreeze solutions perform over time. Although ethylene glycol itself evaporates at a much slower rate than water, any loss through evaporation could affect its overall cooling efficiency. Here’s why:

- Concentration Changes: In a typical antifreeze mixture, ethylene glycol is diluted with water. If water evaporates more quickly, the concentration of ethylene glycol increases, which may alter the freezing and boiling points of the solution. An imbalance like this can reduce its protective qualities and even cause potential damage to cooling system components. For more detailed insights, this discussion on antifreeze evaporation is an excellent resource.

- Long-Term Stability: Over time, even the minimal evaporation of ethylene glycol itself can lead to the depletion of the antifreeze mixture, particularly when the system is not properly sealed. This situation could compromise the integrity of the coolant, making it less effective in extreme temperatures.

- Heat Transfer Efficiency: The efficiency of heat exchange depends on the specific mix of water and ethylene glycol. Lost water or ethylene glycol through evaporation could reduce the overall system efficiency, potentially causing overheating in engines or industrial machinery. Learn more about coolant dynamics in systems from Astrodyne TDI.

Environmental Considerations

The evaporation of ethylene glycol, while minimal, poses environmental risks if improperly managed. Spills or aerosolized contamination stemming from evaporation can affect ecosystems and human safety in several ways:

- Toxicity in Ecosystems: Small amounts of evaporated ethylene glycol could enter the atmosphere, but its real environmental impact emerges when it contaminates soil or water sources. Ethylene glycol is toxic to both wildlife and aquatic life. If it seeps into the environment, it may cause severe damage by depleting oxygen levels in water bodies, a phenomenon described in this Health Canada report.

- Air and Soil Quality: While ethylene glycol has a low vapour pressure and evaporates slowly, when it does disperse into the air, it can pose risks to respiratory health. Its presence is also concerning for soil pollution, where it can impact plant growth and lead to long-term degradation of soil health. For more extensive information, you can explore this Maratek article discussing glycol’s environmental impact.

- Handling and Spill Risks: In cases of improper storage or handling, spills can result in significant environmental challenges. Loose or evaporating ethylene glycol mixtures can combine with water sources, creating toxic runoff. Proper containment and disposal practices are necessary to avoid these issues.

Understanding the evaporation characteristics and challenges associated with ethylene glycol is essential for keeping cooling systems functional and minimizing environmental harm.

Handling and Storage Recommendations

Proper handling and storage of ethylene glycol can make a huge difference in its performance, safety, and longevity. Whether you use it in industrial settings or for more everyday applications like car maintenance, understanding how to store and manage it effectively is key. Below are detailed guidelines to ensure both safety and product reliability.

Storage Best Practices

Storing ethylene glycol properly isn’t just about convenience—it also prevents unnecessary losses and ensures the substance performs as expected. Here’s how to do it right:

- Container Selection: Always store ethylene glycol in durable, non-reactive containers. Materials like stainless steel or high-density polyethylene (HDPE) are excellent choices for preventing corrosion or chemical degradation. Containers must also meet any applicable local regulations for chemical storage. For more specifics on choosing the right storage materials, see this guide on glycol storage.

- Sealing and Tightness: Properly sealed containers are crucial to minimizing exposure to air, which can lead to contamination or oxidization. Ensure the lid or cap fits securely to prevent leaks and reduce evaporation risks.

- Temperature Control: Ethylene glycol should be stored at ambient temperatures, ideally around 20°C (68°F). Avoid extreme heat and direct sunlight, which can degrade the product over time. Heated or chilled environments outside the recommended range can also affect its physical properties. More details on maintaining shelf life and temperature control are available in this glycol storage maintenance guide.

- Positioning and Protection: Always store the containers upright in a cool, dry place, away from incompatible substances like acids or oxidizing agents. Using secondary containment can help prevent spills in the event of a leak.

By following these strategies, you can significantly extend the usability and safety of stored ethylene glycol.

Safety Precautions

Handling ethylene glycol requires attention to detail and the right precautions to avoid risks to health and the environment. Here are some best practices:

- Wear Proper Protective Equipment (PPE): When handling ethylene glycol, always wear chemical-resistant gloves, safety goggles, and long sleeves to minimize skin and eye exposure. This can greatly reduce the chances of accidental contact or spills. Learn more about PPE recommendations from this NIOSH pocket guide.

- Work in Ventilated Areas: While ethylene glycol has low volatility, working in well-ventilated areas can prevent any fumes from accumulating in enclosed spaces. This is especially important for industries working with large volumes.

- Prevent Evaporation Losses: Keep containers tightly closed when not in use. For tasks requiring open containers, minimize exposure time and use lids or coverings to reduce evaporation. If spills occur, clean them immediately using appropriate absorbents to avoid contamination.

- Spill Management and Disposal: Develop a spill response plan that includes immediate containment and cleanup procedures. Dispose of waste according to local hazardous material guidelines. For strategies on proper handling and disposal, refer to this ethylene glycol safety sheet.

- Emergency Safety Measures: Have an eyewash station and safety shower nearby, especially in workplaces where ethylene glycol is used extensively. In case of accidental exposure, flush affected areas with water and seek medical attention right away.

Taking these precautions ensures both safety and efficiency in handling ethylene glycol, whether in small-scale operations or industrial environments. By maintaining a proactive approach, you can avoid unnecessary hazards and improve the overall management of this essential chemical.

FAQs About Ethylene Glycol and Evaporation

Understanding the evaporation properties of ethylene glycol is essential for its safe handling, usage, and environmental impact. Below, we’ll explore common questions about whether or not ethylene glycol evaporates, how it can be detected, and how long this process may take.

Does Ethylene Glycol Evaporate in Open Air?

When exposed to open air, ethylene glycol does not evaporate quickly like water or alcohol. Its low vapour pressure and high boiling point of 197.3°C make it relatively stable under normal conditions. Unlike more volatile substances, ethylene glycol tends to remain in its liquid state for extended periods unless subjected to high temperatures.

However, certain factors can affect evaporation in open-air settings:

- Temperature: Elevated temperatures, such as those found in industrial settings or heated environments, may accelerate the evaporation process slightly, although it’s still minimal.

- Surface Area: The larger the exposed surface area, the more evaporation can occur over time. For instance, if left in shallow, uncovered containers, there could be some measurable losses, but this evaporation is slow.

- Hygroscopic Properties: Interestingly, ethylene glycol is hygroscopic, meaning it can absorb moisture from the air rather than evaporating. This characteristic further limits its volatilization.

For more insights into how ethylene glycol behaves when exposed to air, check out this detailed post on Quora.

Can Evaporated Ethylene Glycol Be Detected?

Detecting ethylene glycol vapours, while rare due to its low evaporation rate, can be crucial in specific industrial or laboratory scenarios. In these cases, specialized tools and methods are employed to measure its presence in the environment:

- Gas Chromatography-Mass Spectrometry (GC-MS): This highly accurate method can detect and quantify ethylene glycol in vapour form or liquid spills. It is commonly used in toxicology and environmental testing.

- Evaporative Light-Scattering Detection (ELSD): Often employed in industrial settings, ELSD can identify trace amounts of ethylene glycol in air or liquid samples.

- Ethylene Glycol Blood Tests: In cases of accidental exposure or poisoning, blood tests can determine levels of ethylene glycol in the human body. While not standard for environmental detection, it’s an essential diagnostic tool. Read more about detection techniques in this clinical guide.

These detection methods are critical not only for workplace safety but also for addressing environmental contamination risks associated with improper storage or accidental releases.

How Long Does It Take for Ethylene Glycol to Evaporate?

The timeline for ethylene glycol’s evaporation depends on environmental factors like temperature, surface area exposure, and airflow. Generally, its evaporation is exceedingly slow under standard conditions. At room temperature, you can leave ethylene glycol exposed for weeks or months without significant losses, unlike fast-evaporating liquids like alcohol or acetone.

- Temperature Dependency: At approximately 160°C, ethylene glycol begins to evaporate more noticeably, even though its boiling point is much higher. This highlights the importance of temperature in influencing the rate of evaporation. You can explore more about this phenomenon in this ResearchGate study.

- Humidity and Airflow: Low humidity and increased airflow conditions can slightly increase evaporation rates. However, these effects remain minimal due to ethylene glycol’s chemical stability and low vapour pressure.

For most practical uses, evaporation won’t significantly affect ethylene glycol’s performance or volume, as it is a highly stable substance. For anecdotal experiences and discussions about this topic, review this Reddit thread.