Safe Hydrofluoric Acid Storage Recommendations

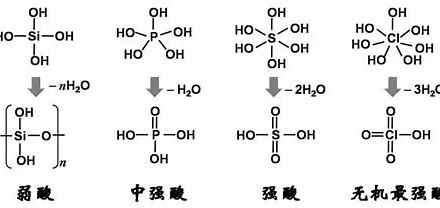

Hydrofluoric acid (HF) is an incredibly unique and hazardous chemical, renowned for its ability to dissolve glass and its severe health implications. While its simple formula HF might suggest a straightforward nature, the chemical structure of hydrofluoric acid (or hydrogen fluoride in its pure form) holds the key to understanding its distinctive and potent properties.

Introduction: The Critical Importance of HF Storage Safety

Imagine a chemical so powerful it can dissolve glass, yet so insidious it can penetrate human skin without immediate warning, causing delayed but agonizing and potentially fatal systemic damage. This describes Hydrofluoric Acid (HF). While it serves as a cornerstone in countless modern industrial processes, its extreme corrosivity and unique toxicity demand an unparalleled level of vigilance in its handling and, most critically, its storage.

Improper HF storage is a direct pathway to catastrophic outcomes: devastating corrosion of equipment, severe skin penetration leading to deep tissue damage, systemic fluoride poisoning with life-threatening cardiac and metabolic disturbances, and uncontrolled environmental release that can harm ecosystems and public health. This article is dedicated to providing comprehensive, actionable safe Hydrofluoric Acid storage recommendations. Our goal is to empower organizations and personnel to effectively mitigate these inherent risks, ensuring a secure environment for everyone involved.

Understanding HF’s Hazards: Why Storage Is So Critical

Before delving into specific storage protocols, it’s vital to grasp the unique dangers that make HF storage a top-tier safety concern:

- Aggressive Corrosive Nature: HF is not just corrosive; it’s exceptionally corrosive. Unlike most acids, it attacks and dissolves almost all materials, including glass, ceramics, concrete, certain plastics (like PVC), and most metals. This means typical acid storage containers or infrastructure are often unsuitable, posing a constant threat of containment failure.

- Rapid Skin Penetration with Delayed Pain: This is perhaps HF’s most insidious characteristic. While it causes severe chemical burns, the initial contact often produces little to no immediate pain. This allows the acid to rapidly penetrate skin and underlying tissues, continuing to cause deep damage for hours or even days before pain becomes apparent. This delayed onset of symptoms can lead to dangerously delayed medical treatment.

- Systemic Toxicity and Hypocalcemia: Once absorbed through the skin, inhalation, or ingestion, the fluoride ion (F⁻) enters the bloodstream. There, it has a dangerously high affinity for vital ions like calcium (Ca²⁺) and magnesium (Mg²⁺). By binding to these ions, it can cause severe hypocalcemia (low calcium levels) and hypomagnesemia, leading to life-threatening cardiac arrhythmias (heart rhythm disturbances), nerve damage, and organ failure. Even small exposures can be fatal.

- Inhalation Hazard: The vapors of HF are highly irritating and toxic. Inhalation can cause severe respiratory tract irritation, pulmonary edema (fluid in the lungs), and chemical pneumonitis, potentially leading to fatal outcomes.

- Reactivity: HF reacts violently with a variety of substances, including strong bases, certain metals (producing flammable hydrogen gas), and other oxidizing agents.

Key Principles for Safe Hydrofluoric Acid Storage: The Foundation of Protection

All effective HF storage recommendations are built upon a set of fundamental principles designed to anticipate and counter its inherent dangers:

- Isolation (Segregation): HF must be strictly separated from incompatible materials that could react dangerously or accelerate its corrosive action. This prevents uncontrolled chemical reactions.

- Containment: The primary goal is to prevent any release. This involves using appropriate containers and implementing secondary containment to capture any leaks or spills immediately.

- Controlled Environment: The storage area must maintain specific environmental conditions, including adequate ventilation and controlled temperature, to minimize vapor accumulation and prevent hazardous reactions.

- Security and Access Control: Only authorized and thoroughly trained personnel should have access to HF storage areas. This prevents accidental exposure, theft, or misuse.

- Emergency Preparedness: Despite all precautions, accidents can happen. Having a robust emergency preparedness plan, including readily available first aid and spill response equipment, is non-negotiable.

Specific Recommendations for HF Storage Containers: The First Line of Defense

The choice and integrity of the container are paramount, as HF’s corrosivity limits suitable materials dramatically.

- Material Compatibility: The Absolute Rule:

- NEVER USE GLASS. This cannot be stressed enough. HF will rapidly dissolve glass, leading to immediate release and catastrophic exposure.

- Recommended Materials: The safest and most common materials for HF containers are specific types of fluorinated plastics. These include high-density polyethylene (HDPE), polypropylene (PP), and especially Teflon (PTFE) or other perfluorinated polymers. These materials offer excellent chemical resistance to HF solutions.

- Metal Containers: While specialized alloys such as Monel, Hastelloy, or certain stainless steels might be used for anhydrous hydrogen fluoride or specific, highly controlled industrial processes, they are generally avoided for aqueous HF solutions due to potential corrosion and hydrogen gas evolution. For typical laboratory and industrial aqueous HF solutions, plastic containers are overwhelmingly preferred for safety.

- Container Integrity and Inspection:

- Always use robust, thick-walled containers specifically designed and rated for corrosive materials. Thin-walled or compromised containers are an unacceptable risk.

- Implement a rigorous schedule for regularly inspecting all HF containers for any signs of cracks, leaks, discoloration, bulging, or degradation. Even minor damage can compromise containment.

- Ensure that all caps and lids are tightly sealed and are made of the same compatible, HF-resistant material as the container itself.

- Labeling: The Silent Warning:

- All HF containers must be clearly, prominently, and indelibly labeled. This includes the full chemical name (Hydrofluoric Acid or Hydrogen Fluoride), its formula (HF), hazard pictograms (e.g., skull and crossbones for toxicity, corrosion symbol), signal words (e.g., “DANGER”), and explicit hazard statements (e.g., “Fatal if swallowed or in contact with skin,” “Causes severe skin burns and eye damage”).

- Include essential identifying information such as the concentration, date received, and date opened.

Environmental Controls for HF Storage Areas: Creating a Safe Microclimate

The immediate environment of HF storage must be carefully managed to minimize risks.

- Ventilation: Dispelling Vapors:

- HF must always be stored in well-ventilated areas. For smaller quantities, a dedicated, properly functioning chemical fume hood is essential. For larger industrial quantities, a dedicated exhaust ventilation system designed specifically for corrosive and toxic vapors is mandatory.

- Ensure sufficient air changes per hour within the storage area to prevent the accumulation of hazardous HF vapors, even from minor leaks.

- Temperature Control: Mitigating Reactivity:

- Store HF in a cool, dry place. Avoid extreme temperatures, both freezing and excessive heat. Freezing can lead to expansion and rupture of containers, while excessive heat increases vapor pressure, accelerating evaporation and potentially increasing reactivity.

- Protect HF containers from direct sunlight, which can cause localized heating and degradation of plastic containers.

- Lighting:

- Use appropriate lighting within the storage area to ensure visibility for inspections and access. However, avoid direct sunlight which can contribute to temperature fluctuations.

Location and Segregation Recommendations: The Principle of Isolation

Where and next to what HF is stored profoundly impacts safety.

- Dedicated Storage Area:

- HF should be stored in a dedicated, clearly marked area, physically separated from all other chemicals.

- Never store HF in general chemical storage areas or alongside incompatible substances.

- Strict Incompatible Materials Segregation:

- This is paramount. HF must be strictly separated from incompatible materials to prevent violent reactions, fire, or the production of hazardous gases. Key incompatibilities include:

- Glassware, Ceramics, Concrete, and Silicate-containing Materials: HF will attack and destroy these, leading to spills.

- Strong Bases/Alkaline Materials: (e.g., sodium hydroxide, potassium hydroxide, ammonia). Reaction with HF is highly exothermic (releases a lot of heat) and potentially violent.

- Oxidizing Agents: (e.g., permanganates, chlorates, nitrates). Can lead to dangerous reactions and gas evolution.

- Certain Metals: (e.g., aluminum, zinc, iron) can react with HF to produce flammable hydrogen gas, creating an explosion hazard.

- Water-Reactive Materials: While HF is dissolved in water, its reactions with other water-reactive materials (e.g., alkali metals) can be extremely violent.

- Implement robust physical barriers, use separate storage cabinets designed for corrosives, or even store HF in entirely different rooms to ensure adequate segregation.

- This is paramount. HF must be strictly separated from incompatible materials to prevent violent reactions, fire, or the production of hazardous gases. Key incompatibilities include:

- Away from Drains/Sewer Systems: Position HF storage well away from floor drains or sewer systems to minimize the risk of environmental release and contamination in the event of a spill.

- Ground Level Storage: Whenever feasible, store HF containers at ground level or on sturdy, low shelves. This minimizes the risk of containers falling and rupturing during handling or in the event of an earthquake. Avoid storing HF on high shelves.

Secondary Containment and Spill Prevention: Preparing for the Unexpected

Even with the best precautions, leaks and spills can occur. Secondary containment is essential for mitigating their impact.

- Mandatory Secondary Containment:

- All HF containers, regardless of size, must be stored within secondary containment (e.g., spill trays, containment pallets, or diked areas).

- The secondary containment volume should be sufficient to hold at least 110% of the volume of the largest single container or 10% of the total volume of all containers within the containment area, whichever is greater.

- The material used for secondary containment must also be chemically resistant to HF.

- Readily Available Absorbent Materials:

- Have appropriate acid-neutralizing absorbent materials readily available near, but not directly within, the HF storage area. Examples include soda ash, calcium carbonate, or specialized HF spill kits designed for acid neutralization. General absorbents like vermiculite may not be suitable as they can react with HF.

Security and Access Control: Preventing Unauthorized Access

Given HF’s hazards, controlling who can access it is paramount.

- Restricted Access: HF storage areas must be locked and accessible only to authorized personnel who have received comprehensive, specific training on HF safety.

- Prominent Warning Signage: Clearly display prominent and unambiguous warning signs indicating the presence of Hydrofluoric Acid and its severe hazards (e.g., “DANGER: HYDROFLUORIC ACID – SEVERE POISON – CORROSIVE”).

Emergency Preparedness for HF Storage Areas: Rapid Response is Key

Even with the most stringent storage recommendations, an emergency involving HF can happen. Rapid and effective response is critical.

- Immediate Access to Emergency Eyewash and Safety Shower: An operational eyewash station and a safety shower must be immediately accessible (within 10 seconds travel time) from any point where HF is stored or used. These must be tested regularly.

- Calcium Gluconate Gel – The Antidote: Crucially, a readily accessible and well-maintained supply of 2.5% calcium gluconate gel must be available at the storage site and its location known to all personnel. This gel is the specific first-aid treatment for HF skin exposures, binding fluoride ions and preventing deep tissue damage. It must be applied immediately and continuously until medical help arrives.

- Dedicated HF Spill Kits: Specific HF spill kits (containing appropriate neutralizing agents, specialized absorbents, and comprehensive PPE for spill response) must be easily accessible, clearly marked, and regularly inspected and restocked.

- Clear Emergency Contact Information: Prominently display emergency contact numbers for poison control, emergency services (e.g., 911), and internal safety personnel.

- Comprehensive Training: All personnel who access, work in, or respond to incidents in the HF storage area must receive comprehensive, recurring training. This training must cover HF hazards, detailed safety guidelines, proper PPE use (including donning/doffing procedures), specific first aid for HF exposure, and precise emergency response procedures for spills and personal contamination.

- SDS Availability: The Hydrofluoric Acid Safety Data Sheet (SDS) must be readily available and accessible to all personnel in the storage area, preferably in a physical binder and electronically.

Conclusion: Proactive Safety Through Diligent HF Storage

Proper storage of Hydrofluoric Acid (HF) is not merely a recommendation; it is an indispensable pillar of workplace safety and environmental stewardship. By meticulously adhering to these comprehensive guidelines – from selecting meticulously compatible containers and ensuring adequate ventilation and temperature control, to implementing robust secondary containment and stringent security measures, and crucially, maintaining robust emergency preparedness – organizations can significantly mitigate the severe hazards associated with HF. Proactive safety through diligent storage recommendations is paramount to preventing incidents, protecting personnel from profound harm, and safeguarding the environment from the dangers of hydrofluoric acid.

Frequently Asked Questions (FAQ)

- Can you store HF in glass bottles? Absolutely NOT. HF readily dissolves glass and will cause immediate containment failure.

- What happens if HF freezes? Freezing HF can cause the liquid to expand, potentially rupturing its container and leading to a hazardous release upon thawing.

- What material is best for HF storage containers? High-density polyethylene (HDPE), polypropylene (PP), and especially Teflon (PTFE) are the most recommended plastic materials due to their excellent resistance to HF.

- How often should HF storage areas be inspected? HF storage areas and containers should be inspected frequently, ideally daily or before each use, and certainly on a regular, documented schedule (e.g., weekly or monthly).

- Where should calcium gluconate gel be stored in relation to HF? Calcium gluconate gel must be stored immediately adjacent to, or within seconds’ reach of, any location where HF is used or stored. Personnel must know its location and how to apply it.

- Is it safe to store HF with other acids? Generally, no. While it’s an acid itself, HF has unique reactivities. It should always be stored separately from other acids, strong bases, and other incompatible materials.

References

- OSHA (Occupational Safety and Health Administration) regulations on hazardous chemicals.

- NFPA (National Fire Protection Association) standards related to chemical storage.

- Manufacturer’s specific Safety Data Sheet (SDS) for the particular Hydrofluoric Acid product being used.

- Professional chemical safety organizations (e.g., American Chemical Society, AIChE).

- NIOSH (National Institute for Occupational Safety and Health) guidance documents on HF.

- [Add specific links to authoritative sources if available, e.g., an OSHA Fact Sheet on HF, or a reputable chemical supplier’s safety page on HF.]