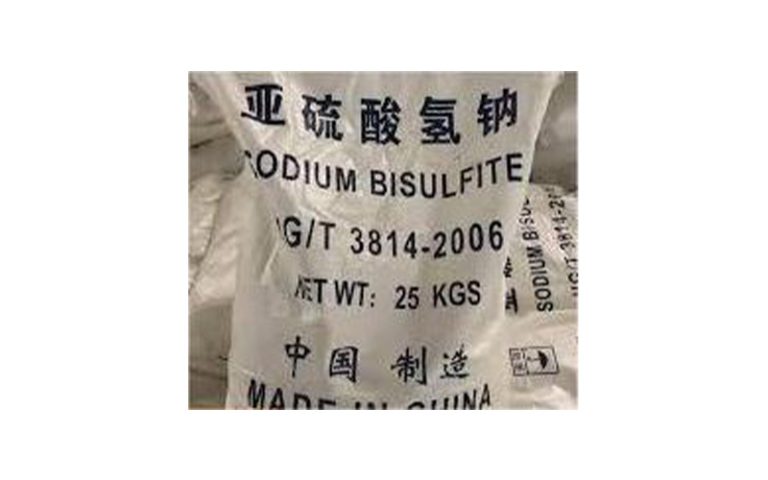

Sodium Chlorate: Your Guide to Bisulfite Specs

sodium chlorate boasts a mass fraction of 64%-67% when calculated as SO2 and adheres to the HG/T 3814-2006 standards. These specifications ensure its effectiveness and reliability in applications ranging from water treatment to food preservation.

Understanding these specifications is vital for industries to achieve desired outcomes. Sodium bisulfite undergoes rigorous testing to guarantee purity, consistency, and efficacy. This ensures users get a product that perfectly meets their needs, similar to how sodium chlorate fits its applications.

Chemical Properties and Composition of Sodium Bisulfite

Molecular Structure

Chemical Formula

Sodium bisulfite, known chemically as NaHSO₃, consists of sodium (Na), hydrogen (H), sulfur (S), and oxygen (O) atoms. This compound forms when sulfur dioxide (SO₂) dissolves in a sodium hydroxide (NaOH) solution. The chemical formula reflects its composition, highlighting its role as a reducing agent in various applications.

Physical State and Appearance

In its pure form, sodium bisulfite appears as a white crystalline powder. This physical state makes it easy to handle and measure for industrial and commercial uses. The powder’s consistency ensures uniform distribution in solutions, which is crucial for its effectiveness as a preservative and antioxidant.

Key Chemical Properties

Solubility

Sodium bisulfite exhibits high solubility in water, which enhances its utility in aqueous solutions. This property allows it to act efficiently as a preservative and antioxidant in food and beverages. Its solubility also facilitates its use in water treatment processes, where it helps remove excess chlorine.

pH Level

The pH level of sodium bisulfite solutions typically ranges from acidic to neutral, depending on concentration. This acidity contributes to its effectiveness as an antimicrobial agent. In acidic conditions, sodium bisulfite releases sulfur dioxide gas, which acts as a preservative by inhibiting the growth of microorganisms.

Reactivity

Sodium bisulfite demonstrates notable reactivity, especially in acidic environments. It releases sulfur dioxide gas when reacting with acids, which boosts its use as a preservative and antioxidant. This reactivity makes it useful in leather tanning and textile dyeing as a bleaching and reducing agent.

Scientific Research Findings:

Sodium bisulfite acts as a reducing agent, catalyst, and preservative in pharmaceuticals and foods due to its antioxidative and antibacterial effects.

It acts as an antioxidant in pharmaceuticals and a disinfectant, bleach, and preservative in winemaking.

In food preservation, sodium bisulfite prevents browning in dried fruits and keeps colors bright, serving as an antibrowning agent.

Common Uses and Applications

Industrial Applications

Water Treatment

Sodium bisulfite plays a vital role in water treatment processes. It acts as a dechlorinating agent, effectively removing excess chlorine from water. This property ensures that water remains safe for consumption and industrial use. Industries rely on sodium bisulfite to maintain water quality, preventing harmful effects associated with chlorine exposure.

Food Preservation

In the food industry, sodium bisulfite serves as a preservative. It prevents the browning of fruits and vegetables, maintaining their freshness and appearance. This compound also inhibits the growth of bacteria and yeast, extending the shelf life of various food products. Its antioxidant properties make it vital in food preservation, keeping products safe and appealing.

Industry-Specific Requirements

Pharmaceutical Industry

The pharmaceutical industry utilizes sodium bisulfite for its antioxidative and antibacterial effects. It acts as a reducing agent and catalyst in the formulation of various medications. Sodium bisulfite ensures the stability and efficacy of pharmaceutical products by preventing oxidation. Its role as a preservative enhances the shelf life of medications, making it indispensable in drug manufacturing.

Textile Industry

In the textile industry, sodium bisulfite functions as a bleaching and reducing agent. It aids in the dyeing process, ensuring vibrant and consistent colors in fabrics. Sodium bisulfite also plays a role in the treatment of textiles, enhancing their quality and durability. Its application in the textile industry highlights its versatility and importance in achieving desired outcomes in fabric production.

Safety and Handling Guidelines

Safe Usage Practices

Personal Protective Equipment (PPE)

When handling sodium bisulfite, individuals must prioritize safety by wearing appropriate personal protective equipment (PPE). This includes gloves, goggles, and protective clothing to prevent skin and eye contact. Proper PPE minimizes the risk of exposure to sodium bisulfite, ensuring safe handling in various environments. Employers should provide training on the correct use of PPE to maintain a safe workplace.

Storage Recommendations

Proper storage of sodium bisulfite is crucial to maintain its efficacy and ensure safety. Store it in a cool, dry place away from direct sunlight and moisture. Containers should remain tightly sealed to prevent contamination and degradation.

Adequate ventilation in storage areas helps avoid the accumulation of any released gases. Following these guidelines ensures that sodium bisulfite retains its quality and effectiveness over time.

Potential Hazards

Health Risks

Sodium bisulfite poses certain health risks if not handled correctly. Inhalation of dust or fumes can irritate the respiratory system, while skin contact may cause irritation or allergic reactions. Ingestion can lead to gastrointestinal distress.

Individuals must adhere to safety guidelines and use PPE to minimize these health risks. Training on proper handling techniques further reduces the likelihood of adverse health effects.

Environmental Impact

Improper disposal of sodium bisulfite can lead to environmental contamination. Releasing sodium bisulfite into water bodies or soil without proper treatment should be avoided.

Compliance with disposal regulations ensures that sodium bisulfite does not negatively impact the environment. Organizations must implement procedures to manage waste responsibly, safeguarding natural resources.

Comparison with Sodium Chlorate

Chemical Differences

Composition and Structure

Sodium bisulfite and sodium chlorate differ significantly in their chemical composition and structure. Sodium bisulfite is an inorganic sodium salt, appearing as a white crystalline powder. It consists of sodium (Na), hydrogen (H), sulfur (S), and oxygen (O) atoms, forming the compound NaHSO₃.

This structure allows it to function effectively as a preservative and reducing agent. In contrast, sodium chlorate has the chemical formula NaClO₃. It comprises sodium (Na), chlorine (Cl), and oxygen (O) atoms.

Sodium chlorate appears as a white crystalline solid and serves primarily as an oxidizing agent. These structural differences highlight their distinct roles in various applications.

Reactivity and Stability

The reactivity and stability of sodium bisulfite and sodium chlorate further distinguish these compounds. Sodium bisulfite acts as a reducing agent, releasing sulfur dioxide gas when exposed to acids or heated to decomposition. This property makes it valuable in preserving food by preventing discoloration and inhibiting bacterial growth. Sodium bisulfite remains more stable than sulfurous acid in aqueous solutions, which enhances its utility in various industries.

On the other hand, sodium chlorate exhibits strong oxidizing properties. It decomposes upon heating, releasing oxygen gas, which can support combustion.

This reactivity makes sodium chlorate useful in applications such as bleaching and disinfection. However, its oxidizing nature requires careful handling to prevent unwanted reactions. Chemical

Sodium bisulfite’s role as a reducing agent and preservative contrasts with sodium chlorate’s function as an oxidizing agent. These differences in reactivity and stability determine their suitability for specific industrial and commercial uses.

Understanding sodium bisulfite specifications is crucial for its effective use across industries. Users should select sodium bisulfite based on its purity and adherence to standards. Proper handling and storage ensure its efficacy and safety.

Industries must store it in well-ventilated areas, away from incompatible substances. Recognizing the differences between sodium bisulfite and sodium chlorate aids informed decision-making. Sodium bisulfite acts as a reducing agent, while sodium chlorate serves as an oxidizing agent. This knowledge helps users choose the right chemical for their specific needs, ensuring optimal results and safety.

yuhan Sodium Chlorate:https://www.yuhanchemi.com/sodium-chlorate

We support product customization Specific specifications, grades, reagents, price comparison is welcome

Contact us:https://www.yuhanchemi.com/contact